The main goal of the 3D-PRESS project was to advance on the 3D printing concepts for safer, cheaper and customizable all-solid state Li batteries (ASSLB). More specifically, the project focused on the design, production, characterization and testing of 3D printed NASICON-type glass-based electrolytes for 3D printed batteries.

3D-PRESS represents a cutting edge multidisciplinary approach for the development of reliable and customizable all-solid state 3D ASSLB, especially interesting for micro-power applications such as for the Internet of Things (IoT). The project provided a new family of printable materials increasing the short list of available compositions, especially solid electrolytes, opening the door to the development of a new generation of fully printable all-solid state 3D batteries with complex architectures.

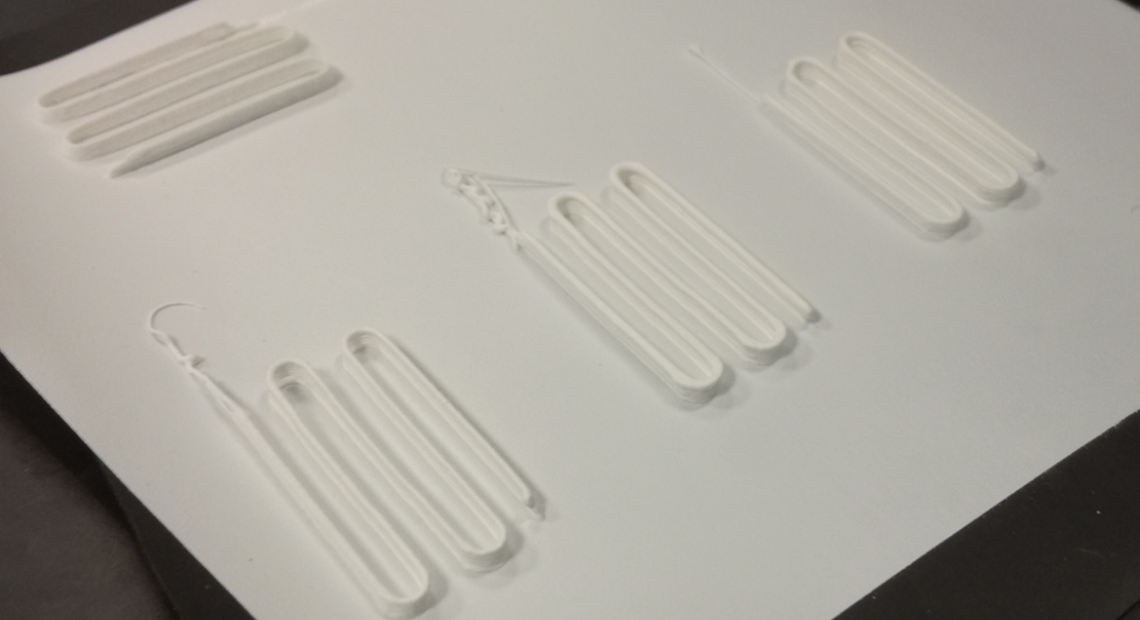

In 3D-PRESS we were able to print Li1.5Al0.5Ge1.5(PO4)3 (LAGP) with two different techniques: robocasting and stereolitography. The complex geometries obtained allowed an increase in the effective area of the electrolyte directly related to a decrease in the area specific resistance of the component. This will allow the production of the next generation of ASSLB with improved energy density. A peer-reviewed paper reporting the main outcomes of the project has been submitted and will soon be available.

The project was carried out by Gianfranco Sabato, who worked in the Nanoionics and Fuel Cells group at IREC since March 2020 until May 2022, thanks to an IF-MSCA-H2020 fellowship.

This project has received funding from the European Union’s Horizon 2020 programme under grant agreement No 841937.