The project “Scale-up of catalyst fabrication for obtaining renewable natural gas” of IREC, aims to scale up the manufacturing of advanced materials for their potential commercialization. These catalysts are designed for renewable natural gas production by the combination of a CO2 emission source and renewable hydrogen. The synthetic gas has the potential to replace the natural gas from fossil origin, since it has the same composition. This technological proposal supports the CO2 circular economy, the chemical storage of wind and photovoltaic energy, the reduction of greenhouse emissions and the reduction of fossil natural gas imports.

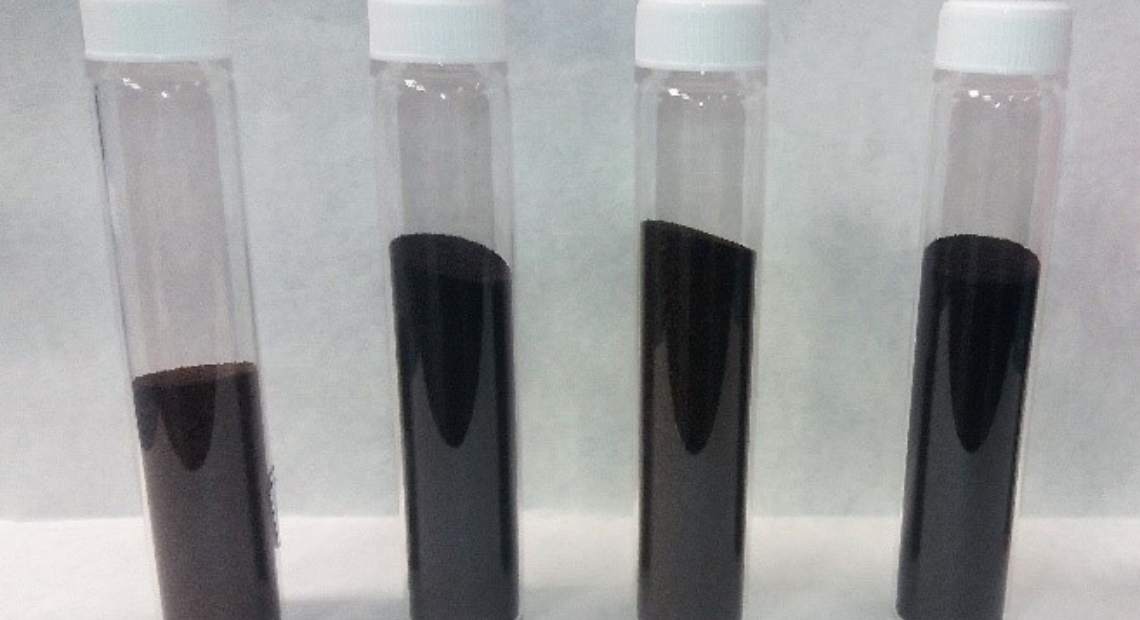

In this process, the catalyst is the key element to carry out the reaction efficiently at moderate temperature and pressures. The proposed catalyst formulation has been successfully tested at a laboratory scale and at a pilot plant located in a waste water treatment plant. The present project aims to optimize the manufacturing process, to adapt it to industrial processes and bring it closer to its commercialization. In this direction, the performance of these catalysts will be tested in a pilot plant of the company Ineratec GmbH that is dedicated to manufacture advanced reactors at European level.

The Catalan’ Government’s Agency for Management and of University and Research Grants (Agencia de Gestió i Ajuts Universitaris i de Recerca (AGAUR)) has awarded this the project with a Llavor grant. The project has a duration of 6 months, a financing of 20,000 euros and is co-financed by the European Union through the European Regional Development fund (ERDF) and supported by the Secretary of Universities and Research of the Ministry for Business and Knowledge of the Government of Catalonia.