The NewSOC project has developed innovative SOCs manufacturing routes that will contribute to the enhancement of the competitiveness of the European solid oxide cells (SOCs) manufacturing industry, while reducing the environmental footprint compared to state-of-the-art processes, especially by reducing the amount of critical raw materials. NewSOC has supposed a step ahead in the technology providing an improvement of the cells in different aspects such as electrochemical performance, carbon tolerance, and redox stability. Also, it contributed remarkably to the reduction of cost and enhancement of the stability under cycling.

The 12 concepts initially proposed in NewSOC have been matched with industry interests, evaluated for matureness and relevance, and have been integrated into industrial cell & stack platforms for experimental validation at relevant scale. All participating industrial partners have demonstrated a considerable openness to receive new developments. Cell components, cells, and stacks were exchanged between industrial and academic partners for integration of improvements and experimental validation.

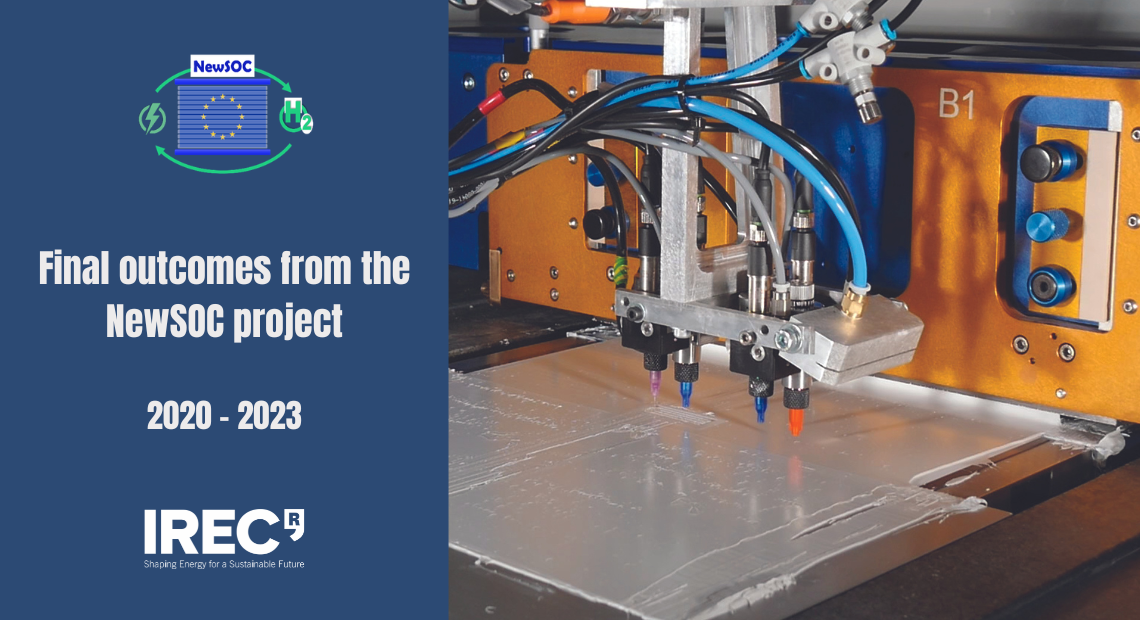

The participation of IREC in the NewSOC project led to a unique technology based on 3D printing of ceramics, which presents the advantages of increasing the design flexibility compared to production lines, simplifying the fabrication process by reducing the number of steps and also reducing the amount of waste material. Large area cells with 3D printed electrolytes were successfully tested over 1000 h in SOFC mode. This activity was carried out by Alex Morata and Lucile Bernadet, with the help of Maritta Lira Dos Santos and Natalia Kostretsova, PhD candidate/students, from the Nanoionics and Fuel Cells group at IREC.

The impact of the NewSOC project relates to achieving targets from the EU wide short- and mid-term climate, energy and transport targets and from the Annual Work Plans of the Fuel Cell and Hydrogen (now Clean Hydrogen) Joint Undertaking. The NewSOC results will have significant impacts such as:

- The improvement of cells in terms of lower area specific resistance and increase of applicable current densities allows for the increase of gas production per given electricity input through electrolysis SOE and a cheaper technology.

- Increasing the durability at constant and dynamic conditions and under specific (for example load / temperature cycling) operating modes contributes to reaching longer lifetimes and a cheaper technology.

- Reducing the manufacturing cost through new methods and reducing use of critical raw materials in manufacturing will improve the economic competitiveness of technology and decrease the environmental impact of production.

All improved NewSOC concepts employ scalable/well-established methodology and can be easily adopted by industry. The NewSOC concepts can be exploited individually or in combinations (such as thinner barrier layers together with improved electrodes). The results were validated in industrial cell & stack platforms within the project. This enables a fast uptake into industrial processes.

All improvements targeted by NewSOC will therefore increase the competitiveness of European SOC technology providers, the economic and environmental sustainability of SOC technologies and will allow for establishment of sustainable energy systems to reach the EU-and worldwide climate goals.

NewSOC is a 3-year EU H2020 project entitled “Next Generation solid oxide fuel cell and electrolysis technology” that finalised in June 2023. The project involved 16 partners from all over Europe, led by DTU, and included 6 major European SOC manufacturers.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 874577.