IREC offers a platform of common services based on its plural technological capabilities and expertise in the field of energy. The platform is conceived as a holding of different common services structured based on knowledge areas to perform technological research and development:

Semi-Virtual Energy Integration Laboratory

The Semi-Virtual Energy Integration Laboratory (SEILAB) provides advanced expertise to assess the development and integration of renewable energy solutions and innovative thermal and electrical equipment that are designed to improve energy efficiency in buildings and energy systems.

SEILAB offers short term feedback-improvement cycles for equipment development, fast determination of Seasonal Performance Factor (SPF), testing/optimising innovative control devices and regulation strategies, evaluation and testing of hybrid energy systems, testing under extreme operating and climate test conditions.

SEILAB offers the following services focused on the testing and emulation of components, such as:

- Micro-Combined Heat Power (m-CHP)

- Fuel cells CHP, ORC and gas boilers

- Photovoltaic and solar thermal collector

- Biomass energy production

- Heat pumps and chillers

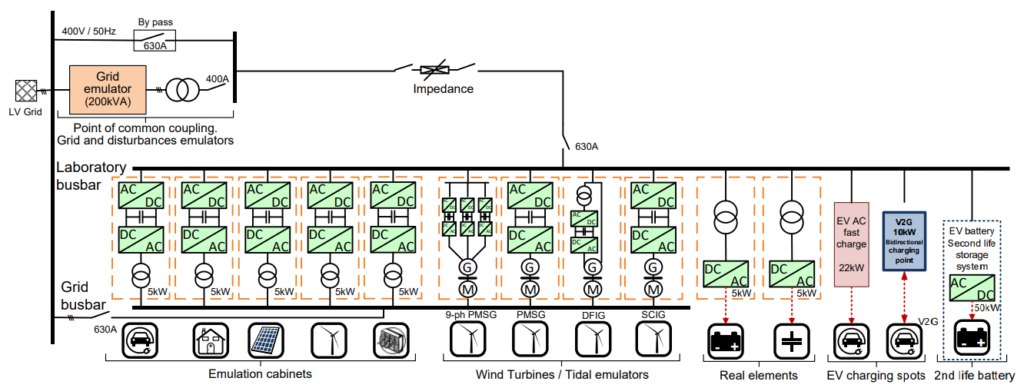

Energy Smart Lab

The Energy Smart Lab service is managed in the area of Energy Efficiency Systems Buildings and Communities (ECOS) and receives the support of the different research groups of the area. This service offers an experimental and testing platform for technology development and testing in a flexible environment. It. can develop and test prototypes in the fields of smart grids and micro-grids, renewable energy sources and electric mobility integration and control, energy storage applications and energy management conceived.

The service is equipped with multiple emulators to control the reactive and active power profiles to simulate both consumption and generation, emulators for the electrical real component of different systems of Eolic generation and ocean currents (SCIG, DFIG and PMSG), equipment for real storage testing such as batteries, second life batteries or super-capacitor, etc. and lines and grid emulators.

The Energy Smart Lab offers the following services:

- Grid code validation

- Pre-certification testing and proof of concept development and experimental testing

- Grid integration testing for generation/storage/load units, immunity to grid disturbances validation, assessment of electrical grid quality (current harmonics and flicker)

- Endurance and performances tests for power systems and grid components

- Battery testing and characterization: evaluation and development of charging and aging algorithmic models, validation, testing and 2nd life batteries behavior characterization

- Testing of EVs electric chargers

- Development and testing of protocols and communication gateways

- Study of cybersecurity vulnerabilities and risks for electric systems

Materials for Energy Labs

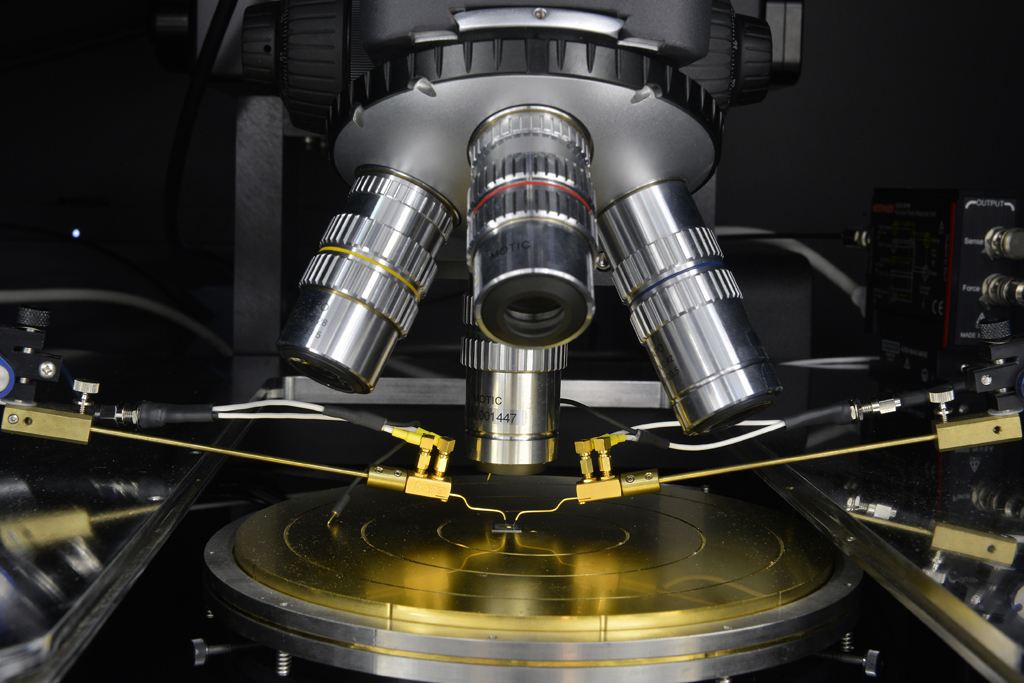

The Materials for Energy Labs also known as “Servicios científico técnicos del área de materiales avanzados” (SCT-MAE) is managed in the area of Advanced Materials for Energy Unit and receives the support of the different research groups of the area. This service offers an experimental setup for synthesizing and characterizing a broad scope of materials as well as the capabilities to assemble and testing energy conversion and storage devices.

These services have fully equipped laboratories for the synthesis and characterization of a wide variety of materials and for the manufacturing and testing of energy conversion and storage devices. Although IREC is a center of excellence in the field of energy, including, among others, photovoltaic energy, electrochemical and chemical energy storage, the generation of synthetic fuels, hydrogen and fuel cells, the SCT-MAE within IREC are used and provide valuable support to various academic and industrial entities of public and private nature in various fields of research and development.

More specifically, IREC SCT-MAE laboratories offer the following services:

· Deposition of bulk and thin film materials by chemical methods: Electrochemical workshop for electrodeposition, spin-coating and screen printing. Chemical laboratories with extraction hoods that include assemblies for sol-gel, CBD and SILAR deposition, ultrasonic baths, hot plates with magnetic stirring, substrate washing, UV ozone cleaner, microbalances; low pressure vapor phase deposition (CVD); atomic deposition systems (ALD)

• Deposition of materials by physical methods: Sputtering systems with DC and RF generators; thermal and electron beam evaporation system; pulsed laser deposition (PLD)

• Annealing chambers for the reactive synthesis and recrystallization of materials: annealing tube furnaces, muffle furnaces and rapid thermal process furnaces (RTP) (80 K), electroluminescence imaging system. Electrochemical characterization stations for batteries or fuel cells (potentiostats, galvanostats, impedance spectroscopy)

• Structural characterization of materials: multi-wavelength Raman-resonant/Photoluminescence systems for the characterization and control of processes, with laser excitation sources between 325 and 1064 nm compatible with mapping up to 60×60 cm2; X-ray diffraction (XRD) system with low angle diffraction for ultrathin layers, temperature and atmosphere analysis; transmission electron microscope (TEM); scanning electron microscope (FESEM); atomic force microscope (AFM) with conductive measurements (c-AFM)

• Compositional characterization of materials: physisorption, chemisorption, chromatography and thermogravimetric analysis methods; Gas Chromatography (GC) and High Performance Liquid Chromatography (HPLC) equipments; X-ray Fluorescence (XRF) and X-ray energy dispersive spectroscopy (EDX)

• Thermal and thermoelectric characterization of materials: thermogravimetric analysis (TGA); Flash equipment for measuring thermal diffusivity; differential scanning calorimetry (DSC) equipment; Seebeck coefficient measurement equipment

· Optical characterization of materials: UV-Vis-IR spectrophotometry; confocal/interferometric microscope; ellipsometer with automatic measurement platform in (0.6- 6 eV)

• Electrical and electrochemical characterization of materials: Kelvin resistivity probe system, Keithley I(V) source meters; C-V impedance system; low temperature electrical measurement station (>80 K), electroluminescence imaging system. Electrochemical characterization stations for batteries or fuel cells (potentiostats, galvanostats, impedance spectroscopy)

• Optoelectronic characterization: Solar simulators (AAA class) for dark and illuminated IV curves; spectral response system for quantum efficiency measurements

• Electrical, optical and opto-mechanical workshops: mechanical tracer, soldering station, microwire bonding systems, encapsulation facilities; electrical and electronic design platform; OEM UV-VIS-NIR spectrometers, CCD and InGaAS detectors, optomechanical modular components, optical design software, mechanical design software, 3D resin printer prototyping system, X-Y motorized tables and actuators

• Advanced in-situ/operating analysis by hybridization of techniques: Simultaneous electrochemical measurements with Raman spectroscopy; electrochemical measurements in operation linked to spectroscopic ellipsometry; Electrochemical measurements using AFM and TERS

• Combinatorial analysis platform: Comprehensive characterization through the combination of different techniques present in the services and data analysis using advanced statistical techniques and artificial intelligence (machine learning) based on Big-Data

Additionally, the SCT-MAE may also offer specialized services based on the experimental capabilities of the research groups depending on the request and the availability. These additional services are:

Energy Storage, Harvesting and Catalysis lab services:

- Battery fabrication, assembly and testing

- Electrochemical testing

- Thermo-, photo- and plasma-catalytic reactors

- Heterogeneous catalyst characterization

- Electrode/catalyst fabrication and thin film deposition

- Reactor modelling (CFD)

Solar Energy Materials and Systems lab services:

- Thin layer deposition by chemical and physical routes

- Synthesis of photovoltaic materials through thermal routes in a reactive atmosphere

- Prototyping and integration of solar cells

- Advanced combinatorial characterization based on compositional, structural, optical and optoelectronic techniques

- Optomechanical and industrial process monitoring workshop

- Advanced data processing unit based on analytical techniques and artificial intelligence

Functional Nanomaterials lab Services:

- Synthesis and characterization of nanomaterials

- Analysis of the photo-, electro- and catalytic properties

- Thermoelectric characterization

Nanoionics and Fuel Cells lab Services:

- Nanostructures and thin films fabrication and characterisation

- Advanced materials fabrication and characterisation

- Electrochemical measurements and performance of devices (from micro- to stack-scale testing)

In this context, IREC is part of Cerca GINYS: the access platform to the scientific and technical infrastructures of the 41 CERCA centres.

Access and pricing:

If you are interested in our services, please contact our Knowledge and Technology Transfer Team (KTT) explaining your interests and experimental needs via the following e-mail: ktt@irec.cat

Please find our service fees here:

Your request will be processed and assessed internally by our service experts and responded shortly after.

The pricing is subject to internal policy and will be adjusted according to the requested service. A detailed definition of the service scope will be defined in the offer.